How Sugar Is Made: A Sweet Journey From Cane Fields To Your Table

Ever wondered how that sweet crystal on your kitchen counter makes its way there? Well, buckle up, because we're diving deep into the sugary world of how sugar is made! It's not just a sprinkle of magic; it's a fascinating process that involves science, nature, and a whole lot of hard work. From the lush green fields of sugarcane to the pristine white granules in your coffee, every step is crucial. Let’s uncover the sweet secrets behind this everyday delight.

The journey of sugar begins with something as simple as a plant. Yes, you heard that right! Sugarcane and sugar beets are the primary sources of this sweet goodness. These plants are cultivated in specific regions around the world, where the climate and soil conditions are just right. But how exactly does this process work? Stick with me, and we'll break it down step by step.

Now, here's the thing: sugar isn’t just a luxury—it’s a necessity for many industries and households. Whether it’s baking your favorite cake or sweetening your morning tea, sugar plays a vital role. So, let's explore the ins and outs of how sugar is made, from harvesting to refining, and everything in between. Ready? Let’s dive in!

Read also:Kristin Ess Curling Iron Review The Ultimate Hair Transformation Tool You Need

Table of Contents

- The Origins of Sugar

- Harvesting the Sweet Crop

- Juice Extraction: The First Step

- Boiling and Crystallization: Where Magic Happens

- The Refining Process

- Different Types of Sugar

- Health Impacts: The Sweet Truth

- Sustainability in Sugar Production

- The Global Sugar Market

- The Future of Sugar Production

The Origins of Sugar

Sugar has a rich history that dates back thousands of years. Believe it or not, sugarcane was first domesticated in Papua New Guinea around 8000 BC. Back then, people chewed on the raw cane to enjoy its natural sweetness. Fast forward to today, and sugar has become a staple in kitchens worldwide. But how did it evolve from a chewy plant to the refined granules we know today?

Here’s the deal: sugarcane cultivation spread across Asia, the Middle East, and eventually Europe. The Crusaders brought it back to Europe in the 11th century, and by the 15th century, sugar plantations were booming in the Caribbean. Over time, advancements in technology and agriculture made sugar production more efficient and accessible.

From Cane to Table: A Brief Timeline

Let’s break it down with a quick timeline:

- 8000 BC: Sugarcane domestication in Papua New Guinea.

- 600 AD: Sugar production begins in India, using rudimentary methods.

- 11th Century: Sugar is introduced to Europe by the Crusaders.

- 15th Century: Large-scale sugarcane plantations emerge in the Caribbean.

- 19th Century: Sugar beet becomes a viable alternative to sugarcane.

So, how exactly is sugar made in modern times? Let’s dive into the harvesting process!

Harvesting the Sweet Crop

Harvesting sugarcane is no small feat. Picture this: vast fields of tall, green sugarcane stretching as far as the eye can see. Sugarcane is typically harvested by hand in many parts of the world, although mechanized harvesting is becoming more common. The timing of the harvest is critical, as the sugar content in the cane peaks during certain seasons.

Once the sugarcane is cut, it’s transported to sugar mills as quickly as possible. Why? Because the sugar content starts to degrade if the cane sits around too long. This is where the real magic begins. But before we get into the nitty-gritty of processing, let’s talk about the other star of the show: sugar beets.

Read also:How To Get Rid Of Textured Skin Your Ultimate Guide

Sugar Beets: The Unsung Heroes

Sugar beets might not be as glamorous as sugarcane, but they account for about 20% of the world’s sugar production. These humble roots are grown in cooler climates, like Europe and parts of the United States. Harvesting sugar beets involves digging them out of the ground and cleaning them before they’re sent off for processing. Pretty cool, right?

Juice Extraction: The First Step

Once the sugarcane or sugar beets arrive at the mill, the first step is juice extraction. For sugarcane, this involves crushing the cane between massive rollers to squeeze out the sweet juice. Sugar beets, on the other hand, are chopped into thin slices called cossettes and soaked in hot water to extract the sugar. It’s like a spa day for the beets, but instead of relaxation, it’s all about releasing that sweet goodness.

Here’s where things get interesting: the juice isn’t pure sugar yet. It contains impurities like plant fibers, proteins, and other goodies that need to be removed. This is where the refining process kicks in, but more on that later. For now, let’s talk about the next big step: boiling and crystallization.

Boiling and Crystallization: Where Magic Happens

Alright, here’s the juicy part (pun intended). The extracted juice is boiled to evaporate the water, leaving behind a thick syrup. This syrup is then further processed to form sugar crystals. It’s like watching a science experiment in action, except the result is something you can actually eat!

But wait, there’s more! The crystals are separated from the remaining liquid, which is called molasses. Molasses is a byproduct of sugar production and is often used in baking or as animal feed. Some of it is even distilled into rum, adding a whole new dimension to the sugary world.

Fun Fact About Crystallization

Did you know that the size of the sugar crystals depends on how long they’re allowed to grow? That’s why you get different types of sugar, like granulated, powdered, and brown sugar. Each one has its own unique texture and flavor profile, making it perfect for different recipes.

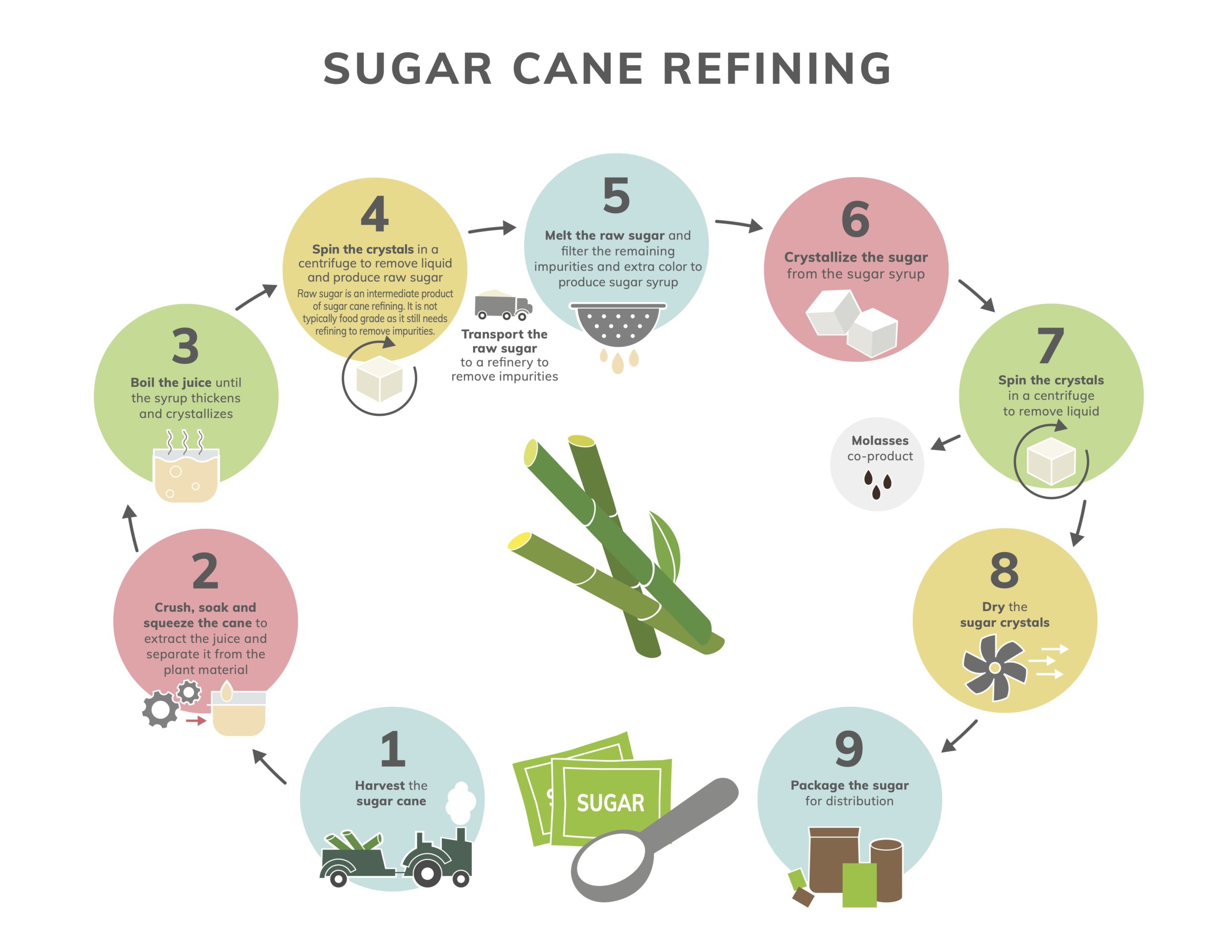

The Refining Process

Now that we’ve got our raw sugar crystals, it’s time to refine them. This is where the sugar is cleaned and purified to remove any remaining impurities. The refining process involves several steps, including washing, filtering, and bleaching. Yes, bleaching! But don’t worry, it’s all done using safe, food-grade methods.

At the end of the refining process, you’re left with the pristine white granules we all know and love. But what about brown sugar? Well, that’s where things get a little extra sweet. Brown sugar is made by adding molasses back to the refined sugar, giving it that rich, caramel flavor we all adore.

Different Types of Sugar

Not all sugar is created equal. Here’s a quick rundown of the most common types:

- Granulated Sugar: The go-to sugar for most recipes. It’s fine, white, and versatile.

- Powdered Sugar: Also known as confectioner’s sugar, this ultra-fine sugar is perfect for icing and dusting.

- Brown Sugar: Made by adding molasses to refined sugar, it has a rich, caramel flavor.

- Raw Sugar: Less refined than granulated sugar, it has a coarser texture and a slightly caramel flavor.

Each type of sugar has its own unique properties, making it ideal for different culinary applications. Whether you’re baking a cake or whipping up a batch of frosting, there’s a sugar out there for every occasion.

Health Impacts: The Sweet Truth

Now, let’s talk about the elephant in the room: the health impacts of sugar. While sugar is delicious, it’s also been linked to a host of health issues, including obesity, diabetes, and heart disease. But here’s the thing: moderation is key. A little sugar in your diet isn’t going to kill you, but overindulging can lead to serious problems.

Many health organizations recommend limiting added sugars to no more than 10% of your daily calorie intake. That’s about 200 calories or 50 grams of sugar for a 2,000-calorie diet. It might sound like a lot, but it adds up quickly when you consider all the hidden sugars in processed foods and beverages.

Tips for Reducing Sugar Intake

Here are a few tips to help you cut back on sugar:

- Read food labels carefully and watch out for hidden sugars.

- Opt for natural sweeteners like honey or maple syrup in moderation.

- Choose whole fruits over fruit juices, which are often packed with added sugars.

- Experiment with sugar-free recipes to satisfy your sweet tooth without the guilt.

Sustainability in Sugar Production

Sugar production has a significant environmental impact, from deforestation to water usage. But many companies are stepping up their game and implementing sustainable practices. For example, some sugar mills are using bagasse, the leftover fibrous material from sugarcane, as a biofuel to power their operations. It’s a win-win for the environment and the bottom line.

Additionally, farmers are adopting practices like crop rotation and organic farming to reduce their carbon footprint. By choosing sustainably produced sugar, you can help support these efforts and make a positive impact on the planet.

The Global Sugar Market

The global sugar market is massive, with billions of dollars in annual revenue. Brazil, India, and Thailand are the top producers, accounting for a significant portion of the world’s sugar supply. But the market isn’t without its challenges. Fluctuating prices, trade tariffs, and climate change all play a role in shaping the industry.

Despite these challenges, the demand for sugar continues to grow. As the global population increases, so does the demand for sweet treats. But with the rise of health-conscious consumers, the industry is also seeing a shift towards healthier alternatives and reduced sugar products.

The Future of Sugar Production

So, what does the future hold for sugar production? Advances in technology and sustainable practices are paving the way for a greener, more efficient industry. From genetically modified crops to innovative processing methods, the possibilities are endless.

But here’s the kicker: as consumers become more aware of the health and environmental impacts of sugar, the industry will need to adapt. Companies that prioritize sustainability and transparency will likely thrive in the years to come. It’s a sweet challenge, but one that’s worth tackling.

Kesimpulan

In conclusion, the journey of how sugar is made is a fascinating one. From the lush fields of sugarcane to the pristine white granules on your kitchen counter, every step is crucial in bringing this sweet delight to your table. Whether you’re a baker, a coffee lover, or just someone who enjoys a little sweetness in life, understanding the process behind sugar production can give you a new appreciation for this everyday staple.

So, what’s next? Why not leave a comment and share your thoughts on sugar production? Or better yet, try making your own sugar-free treats and see how it goes. The possibilities are endless, and the sweet journey continues!

Article Recommendations